As automation replaces manual packing at the end of line, it also removes final inspection of pack integrity. Most packaging machines may at some time produce an inferior pack due to operator error or machine malfunction.

If the line also includes automatic palletizer, this may go unnoticed until the pack is delivered to enduser, leading to claims and returns, hence manufacturers are looking for ways to eliminate or minimize this problem.

The first course of action is to isolate and eliminate the root cause. But sometimes such faults result from cumulative process errors on line, are very infrequent and hard to trace. In such cases the only way to ensure high degree of elimination is by final check at the end of the line.

Depending on packing process, for example, case packing, one can use a check weigher with rejection station to eliminate short count. In case of Shrink bundle packing, visual inspection may be better and perhaps less expensive option.

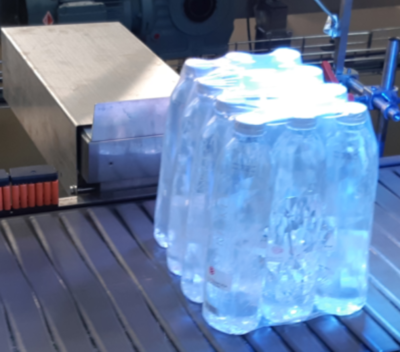

Autopack have recently developed a visual inspection and rejection station using Artificial intelligence (AI) Camera. The device can detect missing cap, deformed shape or missing bottle from the Shrink wrapped bundle.

The system has so far proven reliable and Autopack will soon offer it as a standard option for Autopack range of Shrink, Tray, and Case packing.